Elevate Warehouse Efficiency with Advanced Forklift Tracking

Advanced forklift tracking solutions are designed to enhance your operational efficiency, safety, and productivity in the warehouse. Discover the key benefits and unique features of tracking your forklifts, which will revolutionize your operations.

Explore how Kumi, a leading auto parts manufacturer, optimized their operations with TED™. Witness the seamless automation of workflow, precise task allocation, and resource optimization that propelled Kumi to new heights of efficiency. Learn how TED™ can revolutionize your warehouse and manufacturing processes.

Forklift Tracking for Efficiency

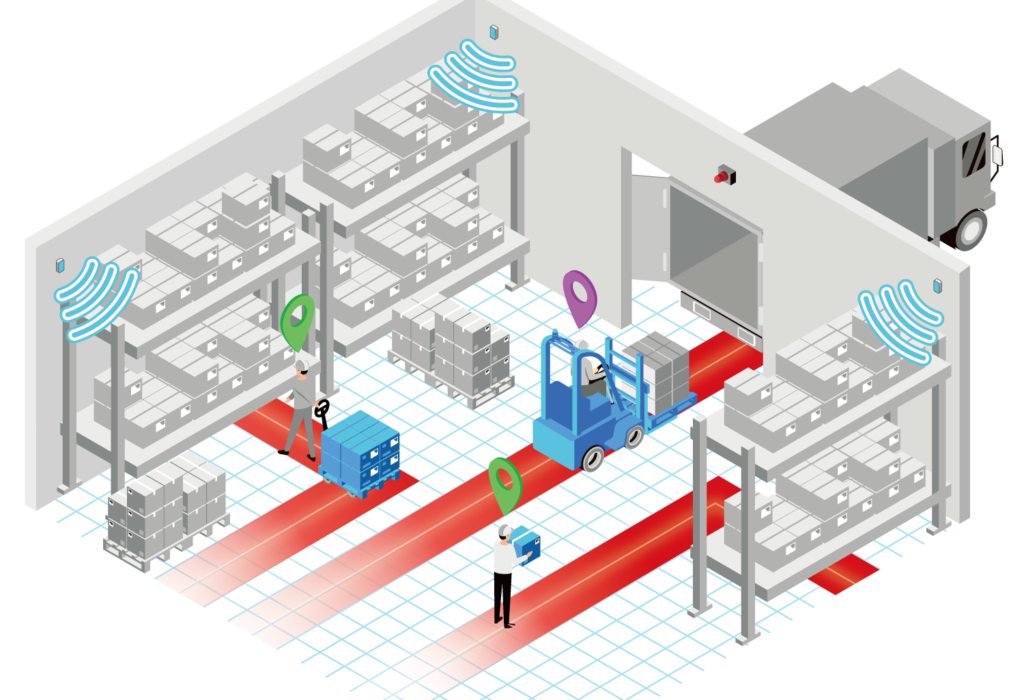

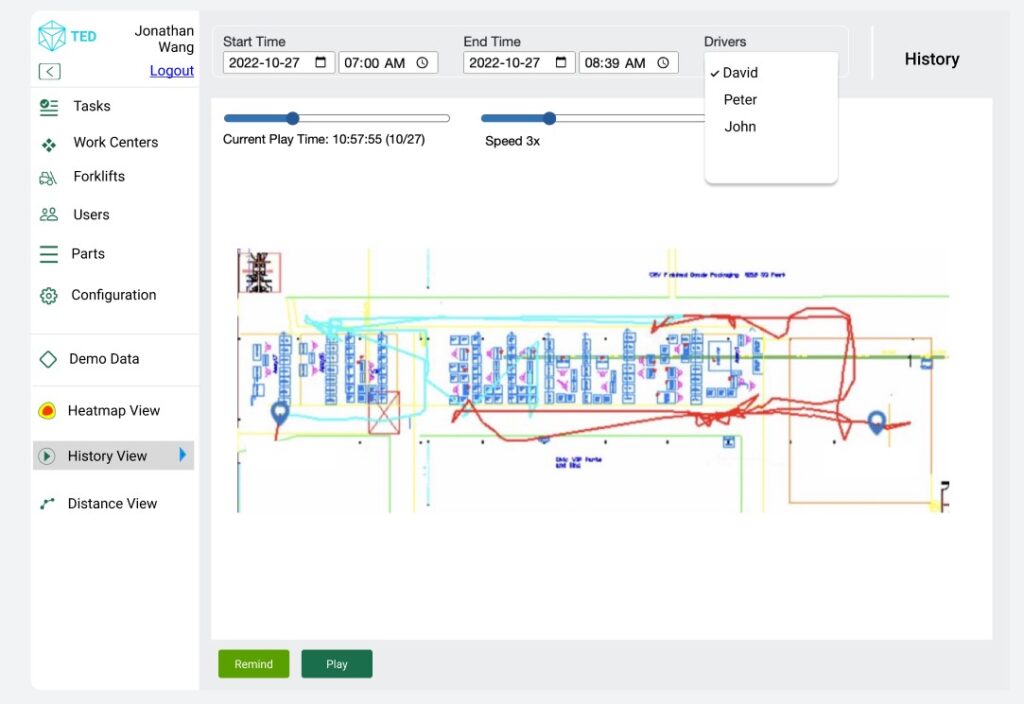

Portable Intelligence’s forklift tracking solution optimizes warehouse operations by providing real-time data on forklift locations and movements. This data helps streamline routes, reduce machine downtime, and maximize efficiency. By utilizing our advanced forklift tracking technology, warehouse operators can ensure their forklifts are always at the right place at the right time, enhancing the overall workflow.

- Real-Time Location Tracking: Showing forklift positions in real-time, allowing immediate adjustments and manual task assigning.

- Optimized Route: Use data-driven insights to plan the most efficient routes, reducing unnecessary driving and searching.

- Task Orchestration – 40% increase in productivity. Our powerful AI determines how best to allocate resources and tasks over the course of a day – ensuring optimal productivity & efficiency.

“We realized that forklift drivers are driving up to 50 km a day on the floor. We were able to change the configuration, reducing their travel time way down, improving their efficiencies. It made a big difference, especially for new associates coming in and driving for the first time. They have no idea where the stuff is and where to go.”

Paul Andrews, Kumi Canada

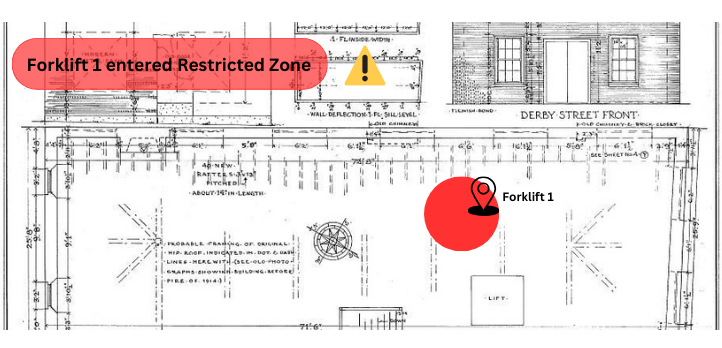

Forklift Tracking for Safety

Portable Intelligence’s forklift tracking system enhances safety with forklift movement traceability and integrated geofencing technology. This ensures compliance with safety standards and reduces accident risks.

When an accident happens, people are able to trace down the time and location for investigation. By using our system, you can create a safer working environment and protect your employees from collisions.

- Collision Alert: Receive real-time alerts to prevent collisions and accidents.

- Speed Monitoring: Ensure forklifts operate within safe speed limits to avoid accidents.

- Geofencing for Restricted Areas: Set up virtual boundaries to keep forklifts or workers out of dangerous or restricted zones. When they approach the boundaries, the tag they carry will buzz as a warning

Our forklift tracking system helps you stay compliant with industry safety standards and regulations, reducing the risk of penalties and enhancing your safety record.

Forklift Tracking and Machine Downtime

Portable Intelligence’s forklift tracking solution significantly reduces machine downtime. Our data shows businesses experience up to 40% less downtime, leading to uninterrupted operations and increased productivity. By using our solution, you can ensure that your forklifts are always operational and ready for tasks.

Reduce Machine Downtime: Identify and eliminate periods of inactivity, ensuring that forklifts are always engaged in productive tasks.

Predictive Maintenance Alerts: Receive alerts for maintenance needs based on real-time data and usage patterns.

Real-Time Performance Monitoring: Track forklift performance to identify and address issues promptly.

Within 6 months, the improved synchronization of production and material movements, resulted in a significant decrease in downtime as both WIP parts and completed parts were handled on a more timely basis by TED.

Forklift Tracking with Task Arrangement and Management

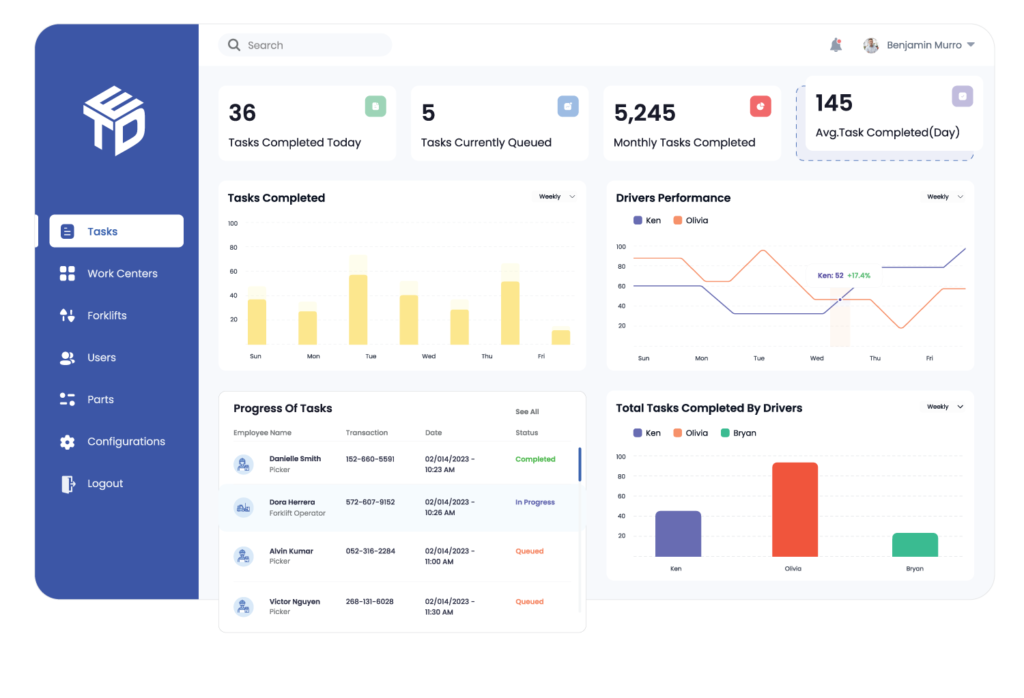

Our forklift tracking system excels in task management, offering features like real-time scheduling, route optimization, and automated reporting. These features help you manage your warehouse tasks more effectively, ensuring that every task is completed on time and efficiently.

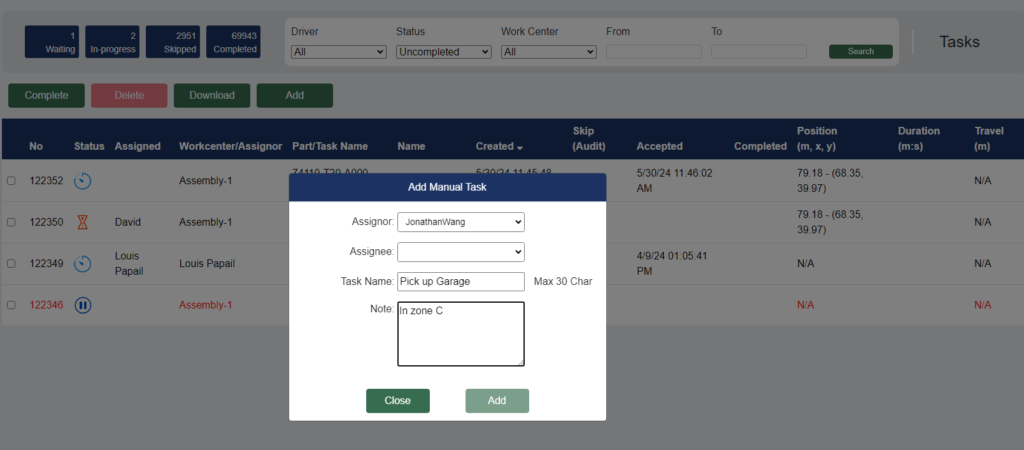

Real-Time Task Scheduling

Assign tasks to forklifts in real-time, optimizing their routes and schedules for maximum efficiency.

Route Optimization

Use real-time data to plan the most efficient routes for each task, reducing travel time and fuel consumption.

Automated Reporting

Generate detailed reports on forklift operator performance and task completion to identify areas for improvement. Get 100% visibility and accountability over task analytics.